ASME TDP-1 PDF

$37.40 – $64.60

Prevention of Water Damage to Steam Turbines Used for Electric Power Generation Fossil Fueled Plants

Description

TDP-2 resolves issues like the identification of any connection to the turbine & treatment of sources causing damage to turbines.

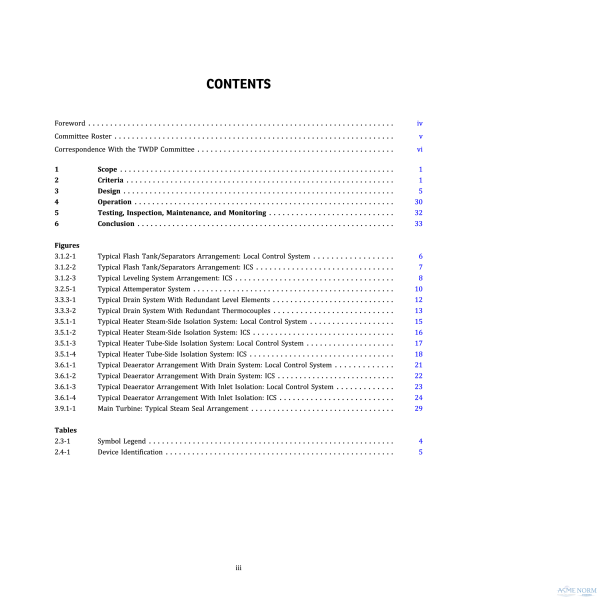

Asme’s tdp-1 standard provides recommended practices prevention water damage steam turbines used fossil-fuel-fired electrical power generation. address due water, wet steam, backflow turbine applicable conventional cycle, combined cycle cogeneration plants. cover design, operation, inspection, testing, maintenance aspects following plant systems equipment concerned preventing induction associated equipment: motive systems;steam attemperation systems;turbine extraction/ admission systems;feedwater heaters;turbine drain seal systems;start-up systems;condenser dumps;steam generator sources. connection potential source either external accumulation condensed steam. sources treated herein specifically found frequently involved causing turbines. although high intermediate pressure historically recognized damaging, experience shown low can cause significant damage. key changes revision include: inclusion mandatory language throughout document;requirements power-operated block valve closures;parameters feedwater heater testing;considerations vertical flash tanks;requirements continuous drains;requirements spray control valves attemperator valves;requirements backflow;addition section instrumentation;addition excess routed condenser. intended anyone engaged safety fossil fuel plants, including responsible for: engineering manufacture; maintenance, monitoring; inspection regulation; insurance liability; facilities management; emergency response.

Please select a variation to view its description.

Please select a variation to view its description.